Technical description of the FWD/HWD measuring system

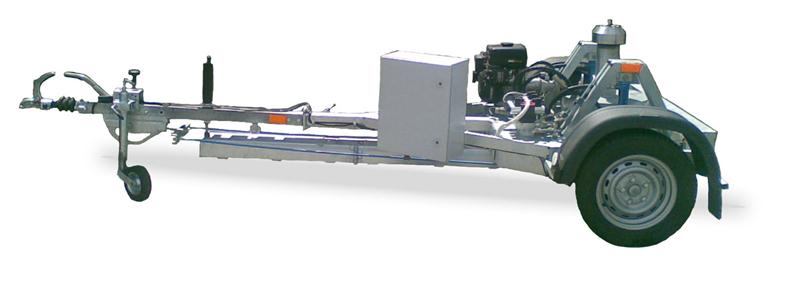

FWD/HWD is a device used for measuring deflections of roads and airfields in a damped manner. t is a two-wheel trailer behind a towing vehicle equipped with a loading device, measuring frame, control and measuring electronics.

The measuring process is controlled from a measuring laptop in the vehicle, which controls all functions using hydraulics self-propelled by a petrol engine. All parts of the machine are galvanized or anti-corrosion. The measuring principle consists in placing the load plate and measuring frame equipped with deflection sensors (geophones) on the road, deriving a load pulse of defined size by falling mass and measuring the deflection line of the road at 7 to 11 points at distances 0 – 2100 mm from the center of the load plate.

From the measured deflection values, the shock modulus of elasticity of the individual structural layers of the road, in the temperature conditions determined during the measurement, is calculated by means of back-calculation, used for calculations of load-bearing capacity, residual service life of the road and its reinforcement.

FWD/HWD dimensions

- length 363 cm

- width 169 cm

- height 117 cm

- hinge height (ball) 45 cm

- weight of falling mass 320/600 kg

- dimensions of folded FWD/HWD (LxWxH) 215x170x100cm

- total weight FWD 900 kg, HWD 1180 kg

Properties

- maximum fall height 47 cm

- working load range 5 – 18 t (FWD), 10 – 30 t (HWD)

- measurement time of a sequence of 3 strokes at the measured point 25 sec

Powering

- 4-stroke Briggs & Stratton 6.5 HP petrol engine with electric starter and alternator

- starting from the measuring laptop or manually with a cord

- the engine drives fast hydraulics, ensuring all mechanical operations, powers the measuring system and recharges the battery

- the solution is independent of the towing vehicle equipment

Electronic equipment

- the electronic control and measuring unit is located on the trailer and connected to the laptop with a USB cable

- load cell for measuring load forces up to 350 kN

- 9 geophones placed on the measuring frame at distances of 0, 300, 450, 600, 900, 1200, 1500, 1800 and 2100 mm from the center of the load plate

Software

- the field program allows you to control the hydraulics of the measuring system automatically or manually

- the field program allows the operator to change all parameters of the measuring process, the number of drops in the sequence (up to 20) and the load force of drops in the sequence

- the field program continuously records the measured data of the load cell and 7 to 11 geophones

- the export program allows you to graphically display time behavior of load pulse and all deflections on any measured point

- the export program allows you to graphically display the deflection curve and all measured data of all active geophones on any measured point

- the export program allows you to create a standard fwd file used to recalculate modules

Accessories

- DMI (Distance Measurement Instrument) integrated into field program

- LCD monitor with camera mounting on trailer for exact placing geophones by measuring joints

- 2 thermometers measuring air temperature and road surface temperature

Measuring laptop

The laptop should be at least 1 GHz, 1024 MB RAM, operating system Windows 2000 and higher, 1 GB of free space on the HD, 2 free USB 2.0 ports.

Connection

The FWD/HWD deflectometer is connected with a USB cable to the laptop and a video cable to the LCD monitor in the vehicle.

Optional equipment

Additional display for measuring the distance traveled

The data on the distance traveled is displayed by default in the window of the measuring program on the laptop. An additional display located in the field of vision is a much more ergonomic solution, but requires connecting the display to the laptop using a USB cable.

Front camera

It is used for taking pictures of the road in a pre-set step and transferring them to a measuring laptop, where they are stored with the station. Photo documentation is an invaluable aid in evaluating measurements. The front camera requires a laptop with a free USB 3.0 port.

Rear extensional bar

The additional measuring frame located behind the trailer is equipped with 2 additional geophones at a distance of 300 and 600 mm from the center of the load plate and serves to refine the shape of the deflection line.